We are shaping the future of the industrial production of composite components.

Process digitization for maximum quality and efficiency.

ALPEX Process Data Solutions was developed as a supplement to our tooling systems and offers a comprehensive, customized technical platform for data-based process control that is perfectly matched to our tooling systems.

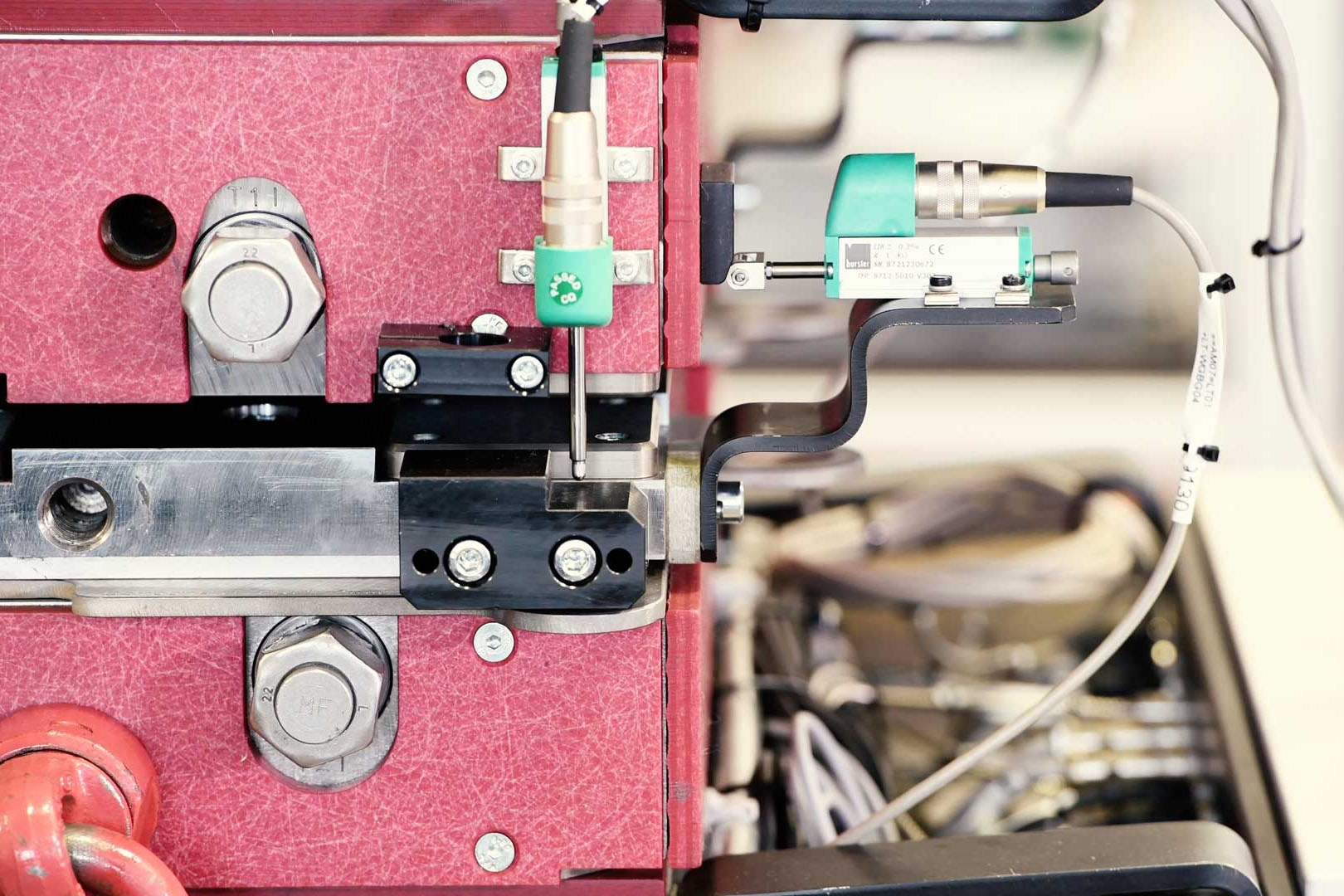

All process-relevant data are recorded and processed in real time based on the process sensors integrated in the tooling system and the tooling status sensors in our ALPEX components.

In close cooperation with our customers, we create a systematic database that ensures consistent component quality and optimized production processes.

COLLECTION

Our tooling systems are enhanced by equipment that enables the collection and combination of signals from all process and tool sensors.

The temporal synchronization and individual sampling of the recorded signals in particular create the basis for resource-saving data storage and efficient further processing of the relevant parameters.

VISUALIZATION

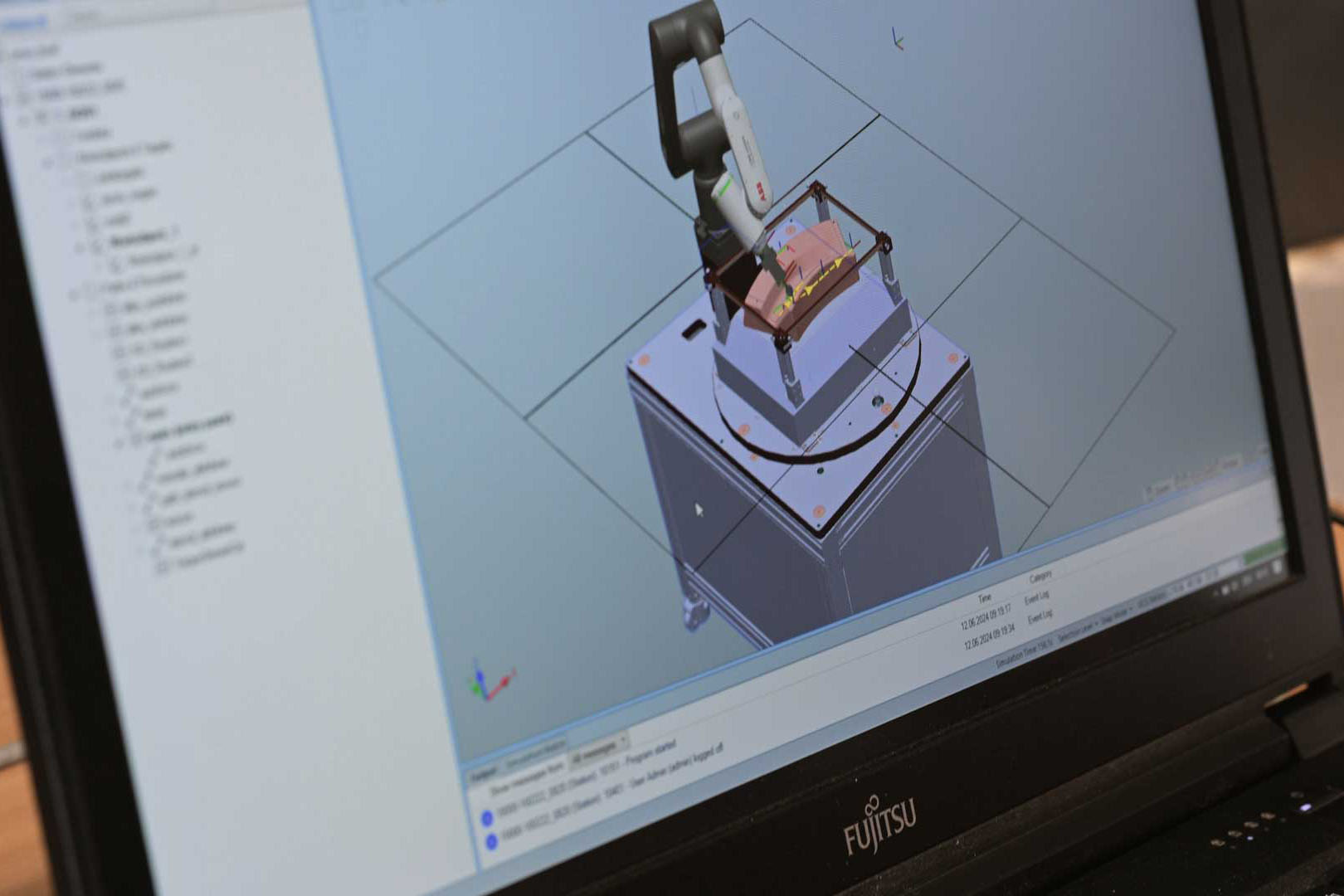

All collected tool-specific parameters and process-relevant data are visualized in real time and shown on a display.

The display of the data and the selection of the output hardware can be configured according to customer requirements.

INTERPRETATION

The visualized real-time data are monitored within action corridors and standard values – derived from past production cycles – in a customer-specific cockpit. This feature enables our customers to track the long-term effects of individual process and tool parameters within our empirical values.

In this way, we make our 25 years of experience in toolmaking and process development systematically available to our customers.

INDIVIDUAL CONFIGURATION

NO DEPENDENCIES OR WORKAROUNDS